GBhydrophilic - Anti-fog / hydrophilic coating

Water droplets and water vapour condensation on smooth surfaces can lead to optical interference and impede the transparency or reflection. Evaporation causes annoying spotting that may also affect the optics and can entail increased cleaning work.

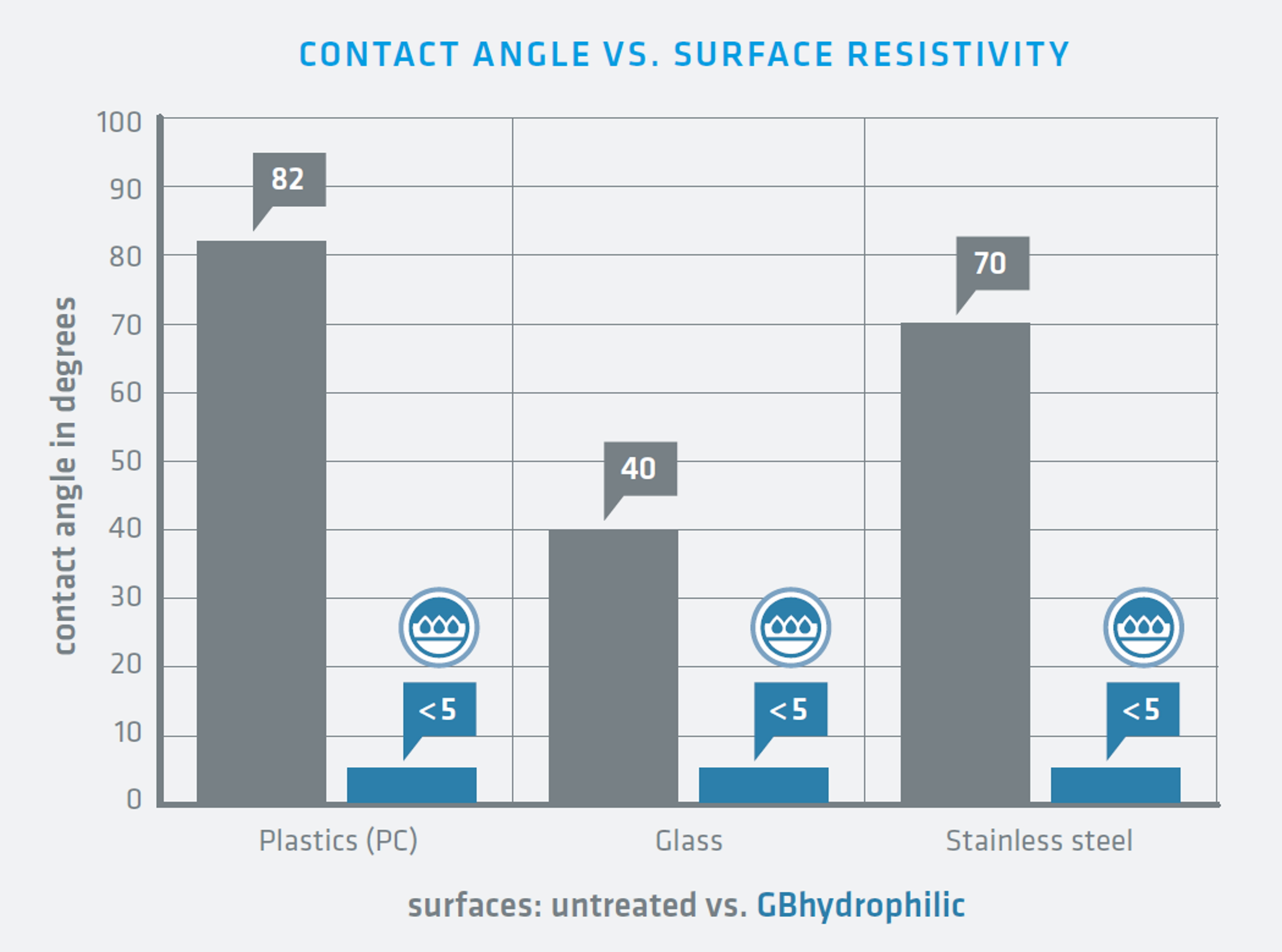

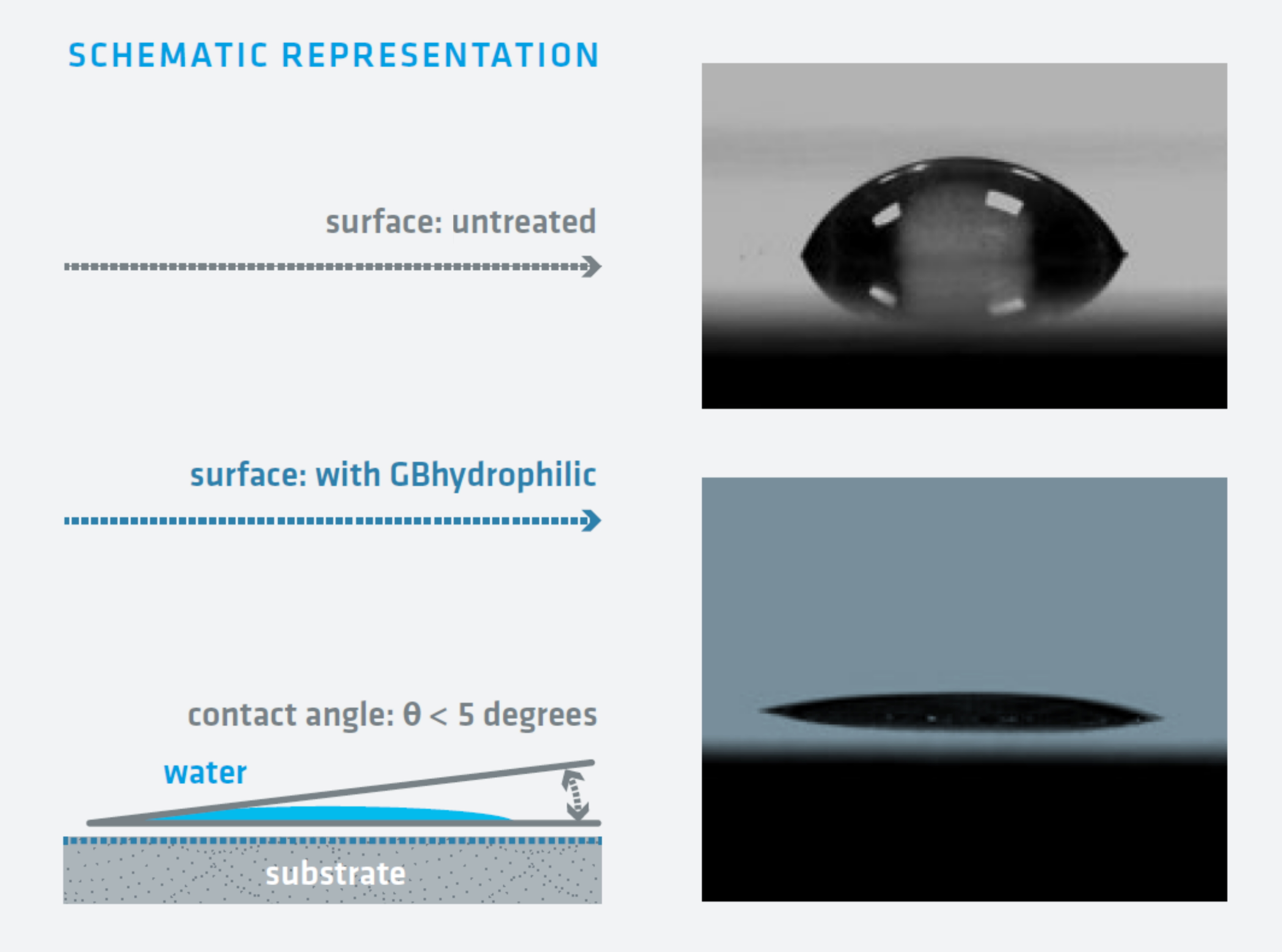

Our clear, transparent hydrophilic coating (anti-fog coating) achieves an improved wetting behaviour of the surface so that fine precipitating water droplets spread to form a cohesive thin film. This creates an anti-fog effect and prevents optical interference. The thin film of water also facilitates evaporation and makes for a cooling effect (greater energy-saving potential).

Properties of nano coating with GBhydrophilic

- contact angle for water θ < 20 ° (according to DIN 55660-3:2011-12)

- maximum temperature load: 200 °C

- film thickness from 5 up to 10 µm

- no change in optical quality of substrate

- scratch-resistant (scratch hardness according to DIN EN ISO 1518 depending on the substrate up to 20 N; pencil hardness

according to DIN EN ISO 15184 up to 10 H) - abrasive hardness (cross-cut test according to DIN EN ISO 2409)

- chemical-proof to customary detergents and disinfection methods

- transparent

- mechanically flexible

Surfaces for hydrophilic coatings

- plastics (PC, ETFE and more)

- glass (borosilicate glass, soda-lime-glass, quartz glass and more)

Application examples for anti-fog coatings

- safety goggles

- coverings

- glasses

- panes

- mirrors

- touchscreens

- and many more

- other surfaces made of plastics ans glass

Dip coating or spraying - manual or automatically

The application process of the antimirobial coating can be matched individually to the geometry and the requirements of the surface.

- certified according to REACH and RoHS

- certified according to ISO 9001:2015; processes comply with IATF 16949

- environmental management conforms to ISO 14001