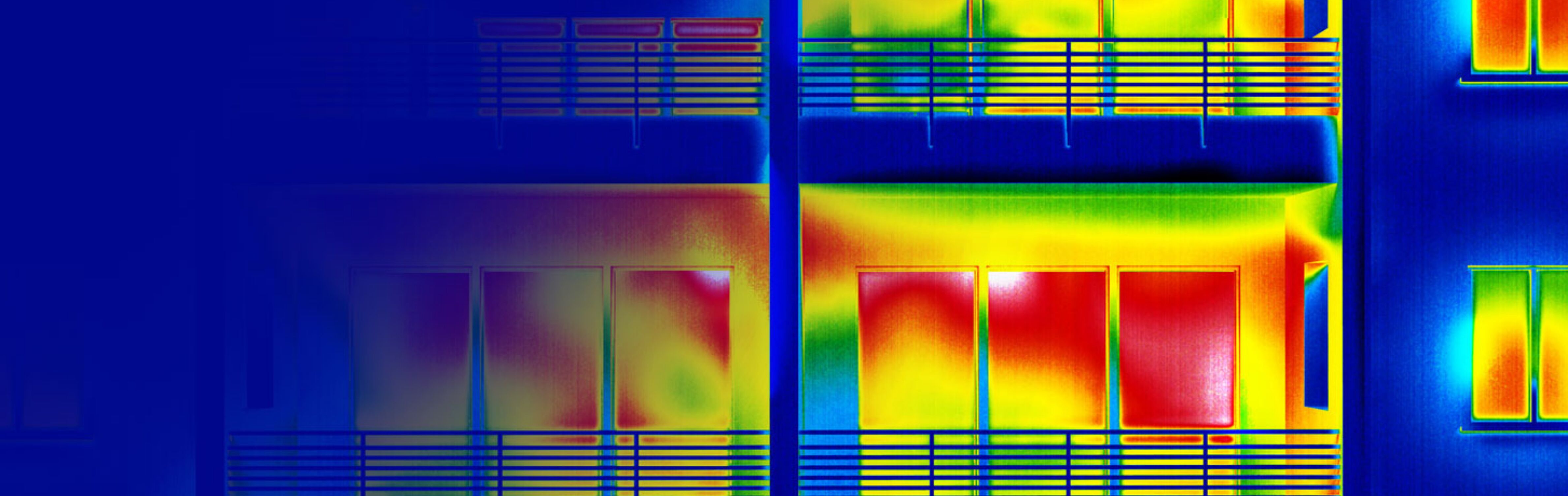

GBheat reflex - Infrared reflective coating

The emission of infrared light, which is invisible to the human eye, from a warm body is called thermal radiation. The thermal radiation that is emitted transports energy so that the radiating body constantly loses heat, which has to be replenished to maintain its temperature. This heat loss consequently leads to rising energy costs.

Our reflective coating GBheat reflex greatly reduces the infrared transmission. The coating thus protects infrared-sensitive substrates and reflects the thermal radiation back into the body, therefore significantly improving the energy efficiency.

Properties of the nano coating GBheat reflex

- increases reflection of light in the infrared range

- protects infrared-sensitive materials and reflects thermal radiation

- maximum temperature load: 500 °C

- film thickness from 50 up to 200 µm

- abrasion resistant (based on DIN EN60068-2-70, minimum 100.000 cycles)

- scratch-resistant (scratch hardness acording to DIN EN ISO 1518: up to 15 N; pencil hardness according to DIN EN ISA 15184: up to 10 H)

- abrasive hardness (cross-cut test according to DIN EN ISO 2409)

- chemical-proof to customary detergents and disinfection methods

Surfaces for IR reflective coatings

- glass (borosilicate glass, soda-lime-glass, quartz glass and more)

Dip coating or spraying - manual or automatically

The application process of the antimirobial coating can be matched individually to the geometry and the requirements of the surface.

- certified according to REACH and RoHS

- certified according to ISO 9001:2015; processes comply with IATF 16949

- environmental management conforms to ISO 14001