GBhydrophobic - Easy-to-clean / hydrophobic coating

Aggressive environmental influences and persistent soiling lead to permanent visual and functional impairments on susceptible substrates. As a result, the time-consuming and costly cleaning effort increases.

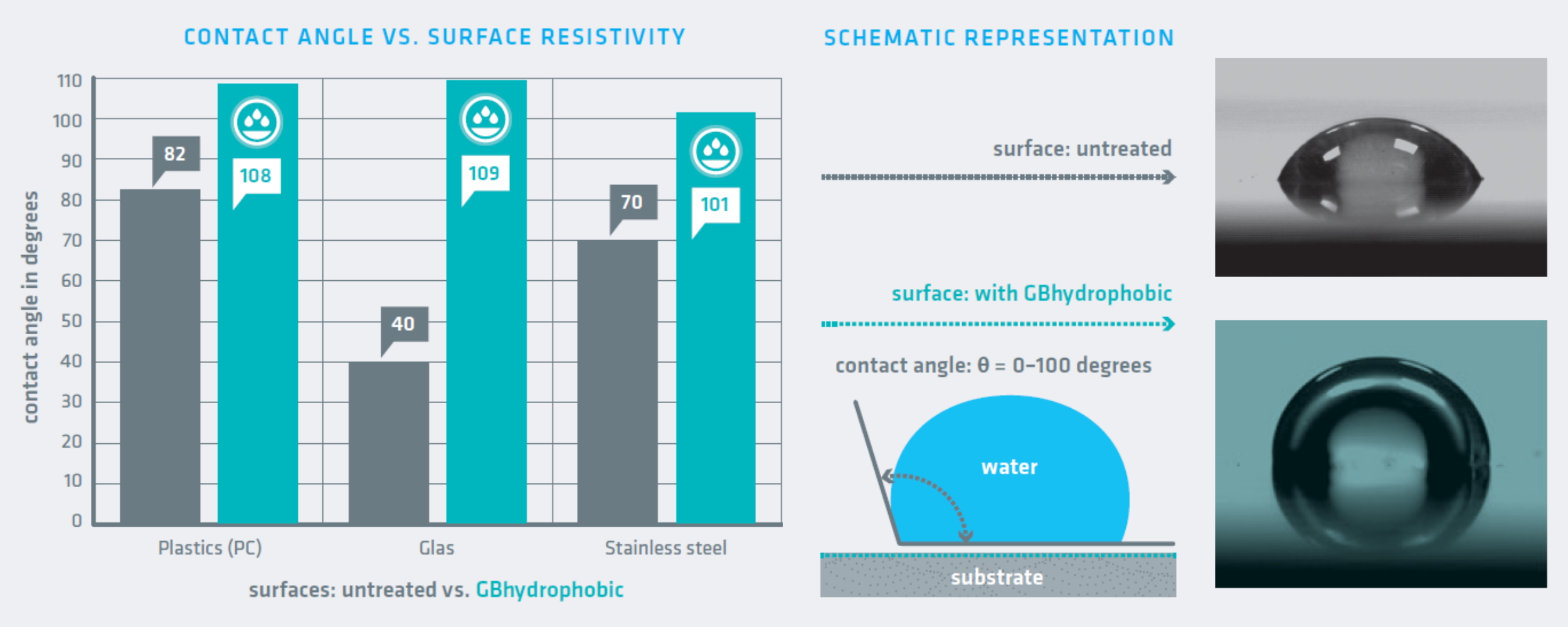

Our hydrophobic coating GBhydrophobic counteracts these negative influences and creates a permanent pearling and non-stick effect against aqueous and organic liquids. The adhesion of dirt particles to the surfaces of the substrate is made noticeably more difficult. The contact of the coated surfaces with water facilitates the removal of these substances. The cleaning effort is thereby reduced (easy-to-clean effect) and surfaces are sustainably protected against aggressive environ-mental influences.

Properties of hydrophobic nano coating with GBhydrophobic

- contact angle for water 0 ≥ 100 ° (according to DIN 55660-3:2011-12)

- maximum temperature load: 200 °C

- combinable with antimicrobial coating SANPURE®

- film thickness from 1.500 up to 2.500 nm

- no change in optic and haptic quality of substrate

- scratch-resistant (scratch hardness according to DIN EN ISO 1518 depending on the substrate up to 20 N; pencil hardness

according to DIN EN ISO 15184 up to 10 H) - abrasive hardness (cross-cut test according to DIN EN ISO 2409)

- chemical-proof to customary detergents and disinfection methods

- transparent, individually coloured on request

Surfaces for hydrophobic coatings

- plastics (PC, PA, PMMA and more)

- glass (borosilicate glass, soda-lime-glass, quartz glass and more)

- metals and alloys (steel, aluminum, copper, brass and more)

Application examples for hydrophobic coatings

- safety goggles

- coverings

- glasses

- panes

- mirrors

- touchscreens

- sensors

- fittings

- knifes

- scissors

- baskets

- other surfaces made of plastics, glass and metals

Dip coating or spraying - manual or automatically

The application process of the antimirobial coating can be matched individually to the geometry and the requirements of the surface.

- certified according to REACH and RoHS

- certified according to ISO 9001:2015; processes comply with IATF 16949

- environmental management conforms to ISO 14001